Electropolished (EP) Seamless Tube

Kodi Electropolishing ndi chiyani?

Electropolishingndi njira yomaliza ya electrochemical yomwe imachotsa chinthu chopyapyala kuchokera kuchitsulo, nthawi zambiri chitsulo chosapanga dzimbiri kapena ma aloyi ofanana. Njirayi imasiya malo owala, osalala, oyera kwambiri.

Amatchedwansoelectrochemical kupukuta, anodic kupukutakapenaelectrolytic kupukuta, electropolishing ndi yothandiza makamaka pakupukuta ndi kupukuta mbali zomwe zimakhala zosalimba kapena zokhala ndi ma geometries ovuta. Electropolishing imapangitsa kutha kwa pamwamba pochepetsa kuuma kwa pamwamba mpaka 50%.

Electropolishing angaganizidwe ngatireverse electroplating. M'malo mowonjezera zokutira zopyapyala za ayoni achitsulo opangidwa bwino, electropolishing imagwiritsa ntchito magetsi kuti asungunule chitsulo chochepa kwambiri cha ayoni mu njira ya electrolyte.

Electropolishing zitsulo zosapanga dzimbiri ndi ntchito yofala kwambiri ya electropolishing. Chitsulo chosapanga dzimbiri chopangidwa ndi electropolished chili ndi chitsulo chosalala, chonyezimira, choyera kwambiri chomwe chimalimbana ndi dzimbiri. Ngakhale pafupifupi chitsulo chilichonse chidzagwira ntchito, zitsulo zomwe zimagwiritsidwa ntchito kwambiri ndi electropolished ndi 300- ndi 400-mndandanda wazitsulo zosapanga dzimbiri.

Kumaliza kwa electroplating kuli ndi miyezo yosiyana yogwiritsira ntchito pazinthu zosiyanasiyana. Mapulogalamuwa amafunikira kumaliza kwapakati. Electropolishing ndi njira yodutsa ndi kuuma kwathunthu kwa Electropolished Stainless Steel Pipe yachepetsedwa. Izi zimapangitsa mapaipi kukhala olondola kwambiri mumiyeso yake ndipo Ep Pipe ikhoza kukhazikitsidwa molondola m'makina okhudzidwa monga ntchito zamakampani opanga mankhwala.

Tili ndi zida zathu zopukutira ndipo timatulutsa machubu opukuta ma electrolytic omwe amakwaniritsa zofunikira m'magawo osiyanasiyana motsogozedwa ndi gulu laukadaulo waku Korea.

EP Tube yathu mu ISO14644-1 Class 5 zipinda zoyera, chubu chilichonse chimatsukidwa ndi ultra high purity (UHP) nayitrogeni kenako ndikumangidwa ndi matumba awiri. Chitsimikizo choyenereza kupanga machubu, kapangidwe kake, kutsatiridwa kwazinthu, komanso kuuma kwapamtunda kumaperekedwa pazinthu zonse.

Kufotokozera

ASTM A213 / ASTM A269

Kuuma & Kuuma

| Production Standard | Mkati Mwankhaza | Ukali Wakunja | Kuuma kwakukulu |

| HRB | |||

| ASTM A269 | Ra ≤ 0.25μm | Ra ≤ 0.50μm | 90 |

Maonekedwe Ogwirizana a Tube

Ripoti la 16939(1)

Njira

Kuzizira kozizira / kujambula kozizira / Annealing / Electropolished

Maphunziro a Zinthu

TP316/316L

Kulongedza

Chubu chilichonse chimatsukidwa ndi gasi wa N2, womangidwa mbali zonse ziwiri, zodzaza m'matumba oyera osanjikiza awiri ndikumaliza m'bokosi lamatabwa.

Chipinda Choyera cha EP Tube

Miyezo Yazipinda Zoyera: ISO14644-1 Kalasi 5

Kugwiritsa ntchito

Semi-conductor/ Zowonetsa/ Chakudya · mankhwala · zida zopangira bio/ mapaipi oyeretsera bwino kwambiri/ Zida zopangira mphamvu ya solar/ Mapaipi opangira zombo zapamadzi

Satifiketi Yaulemu

ISO9001/2015 Standard

ISO 45001/2018 Standard

Sitifiketi ya PED

Satifiketi yoyeserera ya TUV Hydrogen

FAQ

Stainless Steel 316L electropolished chubu ndi mtundu wazitsulo zosapanga dzimbiri zomwe zimathandizidwa ndi mankhwala apadera otchedwa electropolishing (EP). Nazi mfundo zazikuluzikulu:

- Zida: Zimapangidwa kuchokera ku 316L zitsulo zosapanga dzimbiri, zomwe zimakhala ndi mpweya wochepa poyerekeza ndi zitsulo zosapanga dzimbiri 304. Izi zimapangitsa kuti isachite dzimbiri komanso kuti ikhale yoyenera kwa mapulogalamu omwe ali ndi chiopsezo chodziwitsidwa.

- Kumaliza Pamwamba: Electropolishing imaphatikizapo kumiza chubu mu bafa lamagetsi lamagetsi la electrolyte. Njira imeneyi imasungunula zolakwikazo pamwamba kapena pansi pa chubu, zomwe zimapangitsa kuti zikhale zosalala, zofanana. Kukula kwamkati kwamkati kumatsimikiziridwa kukhala ndi ma 10 micro-inchi Ra.

- Mapulogalamu:

- Makampani a Pharmaceutical: Amagwiritsidwa ntchito poyeretsa kwambiri chifukwa chaukhondo komanso kukana dzimbiri.

- Chemical Processing: Zitsanzo mizere kudziwa H2S.

- Ukhondo Paipi Systems: Zabwino pazakudya ndi zakumwa.

- Kupanga kwa Semiconductor: Kumene kusalaza bwino kwa chubu ndikofunikira.

- Zitsimikizo: Zomwe zimalamulira machubu opangidwa ndi electropolished ndi ASTM A269, A632, ndi A1016. Chubu chilichonse chimatsukidwa ndi nayitrogeni yoyera kwambiri, yotchingidwa, ndi matumba awiri muchipinda choyera cha ISO Class 4.

Electropolished chubing ili ndi maubwino angapo:

- Kukaniza kwa Corrosion: Njira yopangira ma electropolishing imachotsa zolakwika zapamtunda, kukulitsa kukana kwazinthu kuti zisawonongeke ndi kuponya.

- Smooth Surface Finish: Mapeto ake ngati galasi amachepetsa mikangano, kupangitsa kuti ikhale yosavuta kuyeretsa ndi kukonza. Izi ndizofunikira kwambiri pamafakitale azamankhwala, kukonza zakudya, ndi mafakitale a semiconductor.

- Ukhondo Wotukuka: Machubu opangidwa ndi ma elekitirodi amakhala ndi ming'alu yocheperako komanso roughness, zomwe zimachepetsa chiopsezo cha kukula kwa bakiteriya. Iwo ndi abwino kwa ntchito zaukhondo.

- Kuchepetsa Kumamatira Kodetsa: Malo osalala amalepheretsa tinthu tating'onoting'ono ndi zowononga kuti tisamamatire, kuonetsetsa kuti zinthu zili zoyera.

- Aesthetics Yowonjezera: Maonekedwe opukutidwa ndi owoneka bwino komanso oyenera kugwiritsa ntchito zapamwamba.

Machubu opangidwa ndi magetsi amagwiritsidwa ntchito nthawi zambiri m'malo ovuta momwe ukhondo, kukana dzimbiri, ndi malo osalala ndizofunikira.

| Ayi. | Kukula | |

| OD(mm) | Thk(mm) | |

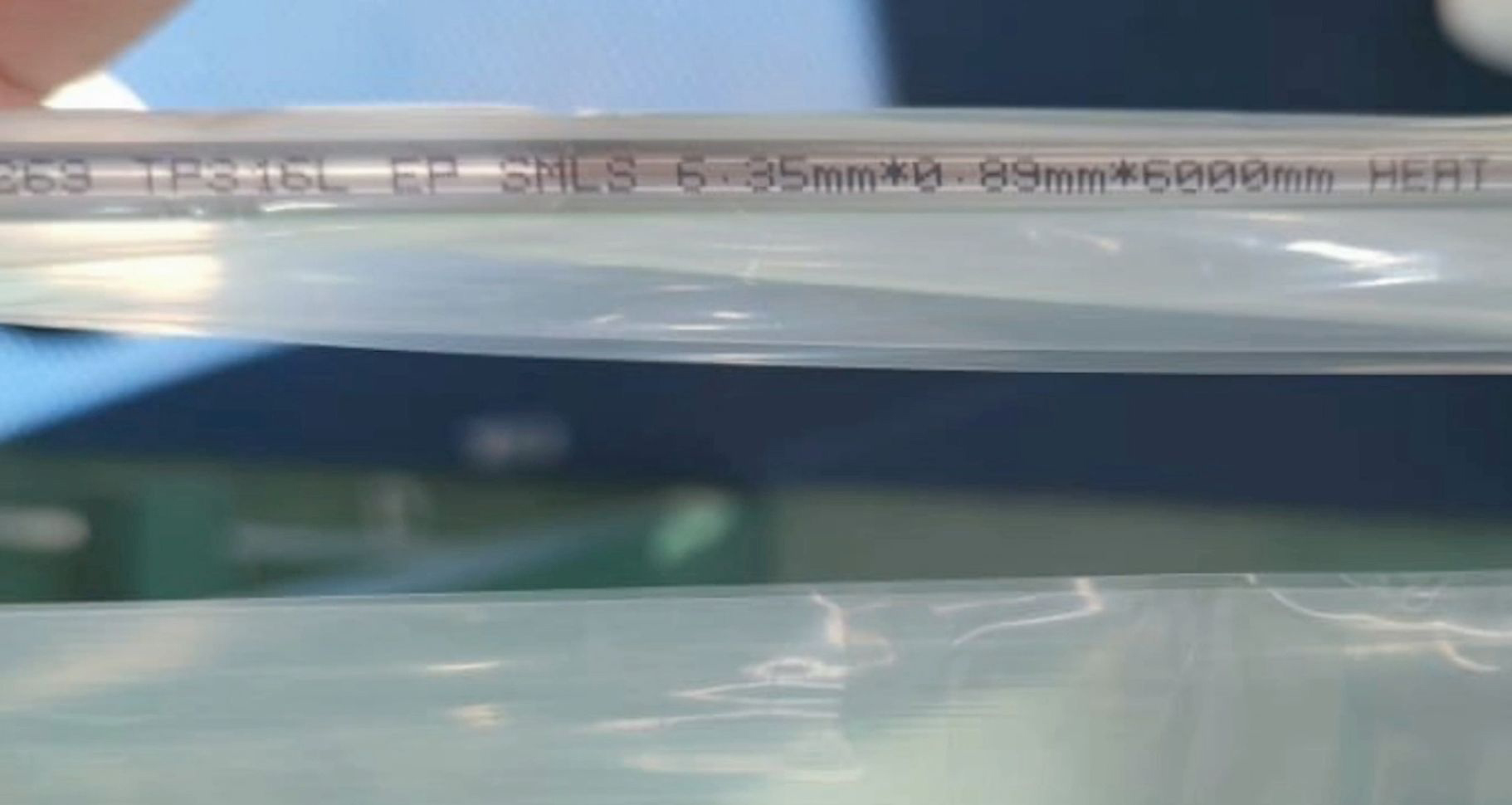

| 1/4″ | 6.35 | 0.89 |

| 3/8″ | 9.53 | 0.89 |

| 1/2″ | 12.70 | 1.24 |

| 3/4″ | 19.05 | 1.65 |

| 3/4″ | 19.05 | 2.11 |

| 1″ | 25.40 | 1.65 |

| 1″ | 25.40 | 2.11 |

| 1-1/4″ | 31.75 | 1.65 |

| 1-1/2″ | 38.10 | 1.65 |

| 2″ | 50.80 | 1.65 |

| 10A | 17.30 | 1.20 |

| 15A | 21.70 | 1.65 |

| 20A | 27.20 | 1.65 |

| 25A | 34.00 | 1.65 |

| 32A | 42.70 | 1.65 |

| 40 A | 48.60 | 1.65 |